Remediation and exploration work in contaminated areas places high demands on occupational safety. Gases and vapours that remain invisible to humans can have dangerous effects even in small quantities. This is why continuous monitoring of breathing air is of central importance. Modern measuring devices make it possible to recognise acute risks such as fire and explosion hazards as well as oxygen deficiency, but also to reliably assess long-term exposure.

At the heart of these protective measures are powerful photoionisation detectors (PID), which have established themselves as a reliable solution for monitoring organic pollutants. With well-founded expertise, the Prof. Burmeier Ingenieurgesellschaft mbH – Member of the SIERA Alliance – projects in the field of contaminated site management and ensures that remediation work can be carried out safely, efficiently and in accordance with regulations. This is another example of the SIERA Alliance’s commitment: Engineering for a Better Tomorrow.

Importance of reliable air monitoring

Air monitoring is an integral part of occupational health and safety when working in polluted soils, contaminated sites or chemically contaminated buildings. It serves two main purposes:

- Recognition of acute dangers:

These include explosive atmospheres, oxygen deficiency or toxic gas emissions. - Assessment of chronic hazards:

Many pollutants develop their effects over longer periods of time. Continuous measurement is therefore necessary in order to recognise limit value violations in good time and initiate appropriate measures.

While multi-gas measuring devices traditionally detect acute hazards, PIDs enable the specific monitoring of organic vapours – a decisive factor in the remediation of contaminated sites, paint shops, chemical plants or former tank farms.

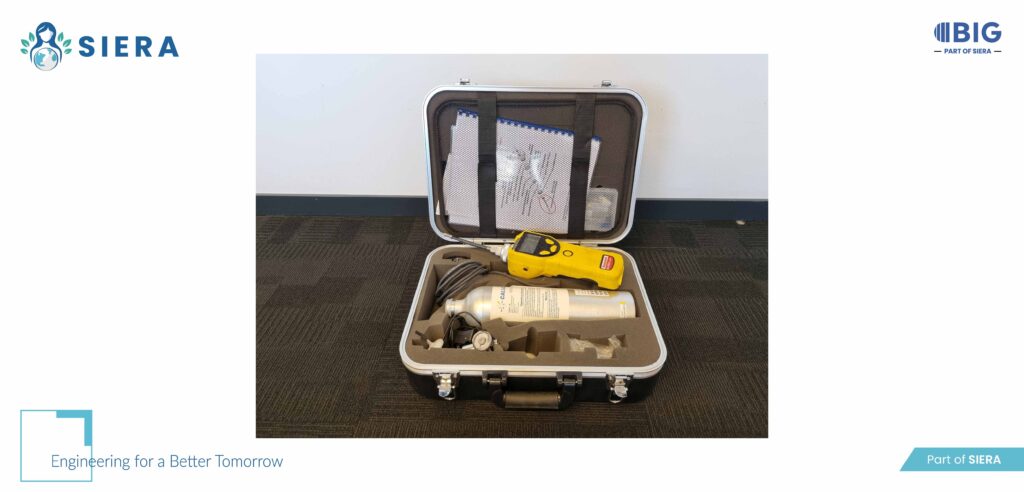

How a photoionisation detector works

A PID is a highly sensitive measuring device based on the ionisation of organic molecules. Its functional structure consists of three central components:

- Internal pump: Draws in the ambient air.

- UV light source: High-energy rays detach electrons from organic molecules.

- Ionisation chamber: Ionisation generates an electric current whose strength is proportional to the concentration of the pollutants.

Electronic amplification and calibration are used to generate a measurable value on the display. Standard calibration is usually carried out with isobutylene – a non-hazardous substance that is ideal for adjusting measuring devices.

Why UV energy is crucial

Not all substances can be ionised. The required ionisation energy of a substance is a physical constant. The higher the energy of the UV lamp, the more substances can be ionised.

Typical UV lamp options:

| UV lamp | Energy (eV) | Recordable substance groups |

| 9.8 eV | low | Selected solvents |

| 10.6 eV | Standard | Alcohols, aromatics, amines, ethers, esters and much more. |

| 11.7 eV | high | Broad spectrum of organic compounds |

The standard for refurbishment work is the 10.6 eV lamp, which already makes a wide range of organic chemicals detectable – including hydrocarbons, aldehydes, acrylates and mercaptans.

Limits and possibilities of a PID

A PID provides Sum signals, no individual substance identification. This means:

- Individual substances cannot be determined in isolation.

- If individual substances are known to be present, additional tests must be carried out in the laboratory.

- To correctly assess hazards, the percentage composition of the air components is crucial.

Exact threshold values can only be derived through laboratory analyses, above which protective measures such as ventilation fans, extraction systems or personal protective equipment become necessary.

These correlations illustrate why the use of trained specialists is essential. Measurement results must be interpreted expertly in order to organise work areas safely. This is precisely where the Prof. Burmeier Ingenieurgesellschaft mbH – Member of the SIERA Alliance – with expertise, experience and modern measurement technology.

Typical areas of application in the environmental and contaminated sites sector

The possible applications of a PID are diverse and closely linked to working practice in environmental and contaminated site management. These include

- Continuous monitoring during renovation work

z. e.g. in the case of soil air pollution caused by BTEX, LHKW or other volatile organic compounds. - Inspection of drill cores

to quickly assess whether solvents or other pollutants are present in the substrate. - Leak detection in industrial plants

Early detection of substance leaks in technical installations. - Containment of damage areas in the event of chemical accidents

Quick orientation for emergency services to secure danger zones.

In all these cases, PGD serves as a reliable screening tool that enables quick decisions to be made.

Professional implementation by trained personnel

The results of PID measurements require expertise and experience. Only trained specialists can:

- Classify measured values correctly,

- Correctly assess limit value violations,

- derive the necessary protective measures,

- Create documentation in accordance with technical regulations.

Prof. Burmeier Ingenieurgesellschaft mbH – a member of the SIERA Alliance – provides qualified personnel and state-of-the-art measuring equipment for this purpose. In contaminated site remediation projects, the company supports clients in creating safe working conditions – from preparation and measurement monitoring to final assessment. In this way, the company contributes to the safe execution of work in contaminated areas and thus follows the guiding principle of the SIERA Alliance: Engineering for a Better Tomorrow.

FAQ

1. Why is a PID important for refurbishment work?

Because it detects organic pollutants in the air very sensitively and thus makes health and explosion hazards visible at an early stage.

2. Can a PID differentiate between individual substances?

No, it measures total concentrations. Laboratory tests are required for individual substance analyses.

3. How often does a PID need to be calibrated?

Regularly, often before each use. The standard calibration is carried out with isobutylene.

4. Are UV lamps replaceable?

Yes, the number of detectable substances varies depending on the lamp.

5. Who is authorised to carry out PID measurements?

Only trained specialists, as the evaluation of the measurement results requires specialised knowledge.

Conclusion

Sound air monitoring is the key to safe remediation work in contaminated areas. Photoionisation detectors offer an efficient and fast way of detecting organic pollutants in the air – provided they are used correctly.

Thanks to the combination of qualified personnel and state-of-the-art measurement technology, the Prof. Burmeier Ingenieurgesellschaft mbH – Member of the SIERA Alliance – reliable metrological support for contaminated sites and remediation projects. In this way, the company creates safety, transparency and trust – today and in the spirit of the common claim of the SIERA Alliance: Engineering for a Better Tomorrow.

➡️ Get in touch now:

Find out how Prof. Burmeier Ingenieurgesellschaft mbH – a member of the SIERA Alliance – can provide professional support for your refurbishment project.